WVU Study of Rare Earth Elements Moves to Second Phase

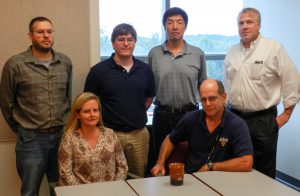

Members of the Rare Earth Recovery team with a sample of AMD based rare earth feedstocks, Wednesday, August 23, 2017.

Back Row (left to right): Chris Vass, REE extraction plant operator; Dr. Aaron Noble, associate professor, Department of Mining and Minerals Engineering, Virginia Tech; Dr. Xingbo Liu, professor of mechanical engineering, Statler College of Engineering and Mineral Resources, West Virginia University; John Adams, West Virginia University Energy Institute. Front Row: Jennifer Hause, project coordinator, West Virginia Water Research Institute at West Virginia University; Dr. Paul Ziemkiewicz, director, West Virginia Water Research Institute at West Virginia University.

The U.S. Department of Energy’s National Energy Technology Laboratory has selected West Virginia University to move forward with its program to extract valuable rare earth elements, vital to the technology industry, from coal mining by-products.

Phase two of the WVU project – which includes $3.38 million of federal and industry funding – will demonstrate the technical and economic feasibility of extracting rare earth elements from acid mine drainage, or AMD. The selection follows two earlier NETL awards to study AMD as a feedstock to bolster U.S. domestic supplies of rare earth elements.

Rare Earth Elements have significant value, being used in modern technologies such as cell phones, rechargeable batteries, DVDs, GPS equipment, medical equipment and various defense applications. Conventional rare earth recovery methods are difficult, expensive and generate large volumes of contaminated waste. Because of this, the U.S. imports nearly all of its rare earth needs from China.

WVU’s project, “Recovery of Rare Earth Elements from Coal Mine Drainage,” will develop a new, domestic source of rare earth elements that will be easily extracted, operate on already permitted sites and produce negligible, new waste materials. In fact, the process may emerge as a way for land owners to generate income from formerly mined properties.

“Mine drainage from abandoned mines is the biggest industrial pollution source in Appalachian streams,” said Dr. Paul Ziemkiewicz, director of West Virginia Water Research Institute and principal investigator on the project.

“As a result, lots of streams that were once ecologically dead, such as the Monongahela and Cheat Rivers, are now valuable recreational fisheries.

“When NETL announced its interest in rare earth recovery it became clear that the mine drainage could be an attractive feedstock for rare earth production. Our research has since focused on finding ways to capture this rare earth resource while incentivizing mine drainage treatment. This project will be a perfect fit to WVU’s mission to create economic opportunity for West Virginians.”

Ziemkiewicz, along with co-investigators Dr. Xingbo Liu, professor of mechanical engineering from the Statler College of Engineering and Mineral Resources at WVU and Dr. Aaron Noble, associate professor at Virginia Tech’s Department of Mining and Minerals Engineering will install a small-scale, continuous extraction facility on the WVU campus.

“The economics of recovering rare earth elements from coal mine drainage appear favorable, and this project will give us the opportunity to develop and optimize the critical separation technologies that will enable commercial-scale production,” said Noble.

The research team will partner with Rockwell Automation to adapt their sensor and control technology and facilitate market readiness. Paul McRoberts and Pete Morell will represent Rockwell Automation on the project team. A global supplier of controls, the company will ensure the success of the project by providing solutions and support services to manage the complex components that will comprise the rare earth extraction process.

John Adams from the WVU Energy Institute will then develop a commercialization plan to move the technology into the marketplace.

-WVU-

ahs/08/24/2017

CONTACT: Paul Ziemkiewicz, West Virginia Water Research Institute

304.293.6958, [email protected]

Related Press Releases: